Static Safe

ATS Inc. is proud to offer the only FM approved duct available with a StaticSafe™ conductive liner.

ATS StaticSafe Duct™ maintains all the features of ATS FXP™ which has made ATS Inc. a leader in the field of Exhaust Duct Systems:

- Corrosion Resistance

- Fire Resistance

- Strength

- No Leakage at Joints

- Extremely low emission of VOCs during installation

- Ease of Installation

- Ease of Modification on a live system

- Low weight to strength ratio

In addition to the benefits of ATS FXP™, ATS StaticSafe Duct™ offers additional protection against static discharge when exhausting flammable or explosive gases.

| Chemical Applications – Flammables | ||

|---|---|---|

| Flammable Gases | Flammable Liquids/Vapors | Pyrophoric Gases (explosive when mixed with air and must be blanketed with nitrogen or argon) |

| Ammonica | Isopropyl Alcohol | Diborane |

| Arsine | Methanol | Silane |

| Dichlorsilane | ||

| Hydrogen | ||

| Phosphine | ||

For part types and dimensions for StaticSafe Duct™, refer to the Mechanical Drawing Guide (Pg. 54) for ATS FXP™.

Composition of StaticSafe Duct™

Internal Corrosion Resistant Conductive Liner

StaticSafe’s™ high corrosion resistance compliments its conductivity to make a product that is desirable for corrosive exhaust applications where there is the potential for venting explosive gases and static dissipation is required.

External Fire Resistant Shell

ATS uses a low smoke, fire safe resin to provide a rigid structural shell, which encloses the corrosion resistant conductive liner.

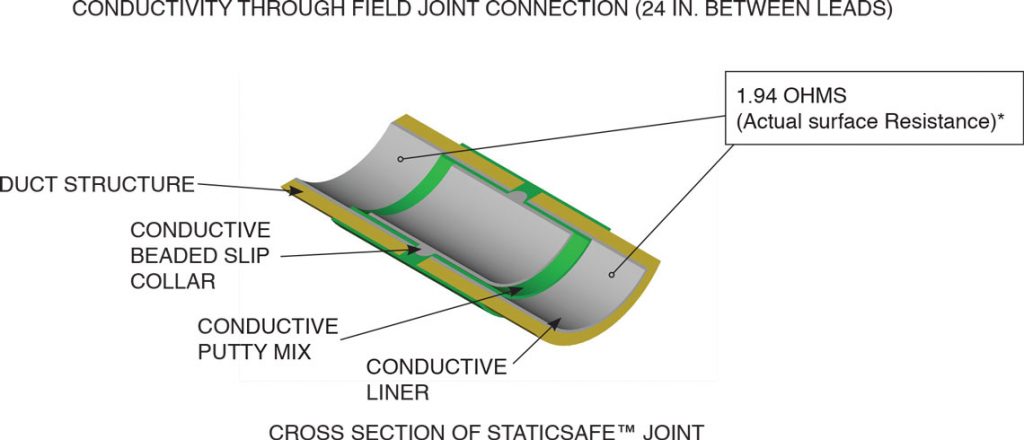

ATS Conductive H-Collar™ and ATS Conductive Slip Collar™ with ATS Conductive Putty™ are used for joining duct sections. There is no need for using cumbersome grounding straps or wires across joints! The joints themselves are conductive. The StaticSafe Duct™ system is self-grounding.

ATS StaticSafe Duct™ is Factory Mutual FM4922-Approved.Factory Mutual Approvals approves ATS StaticSafe Duct™ to be used for fume and smoke removal in cleanrooms without the need for interrupters or automatic sprinkler protection.

ATS StaticSafe Duct™ is also FM 4910 Approved. It meets FM’s requirements for smoke damage (SDI) and fire propagation (FPI).

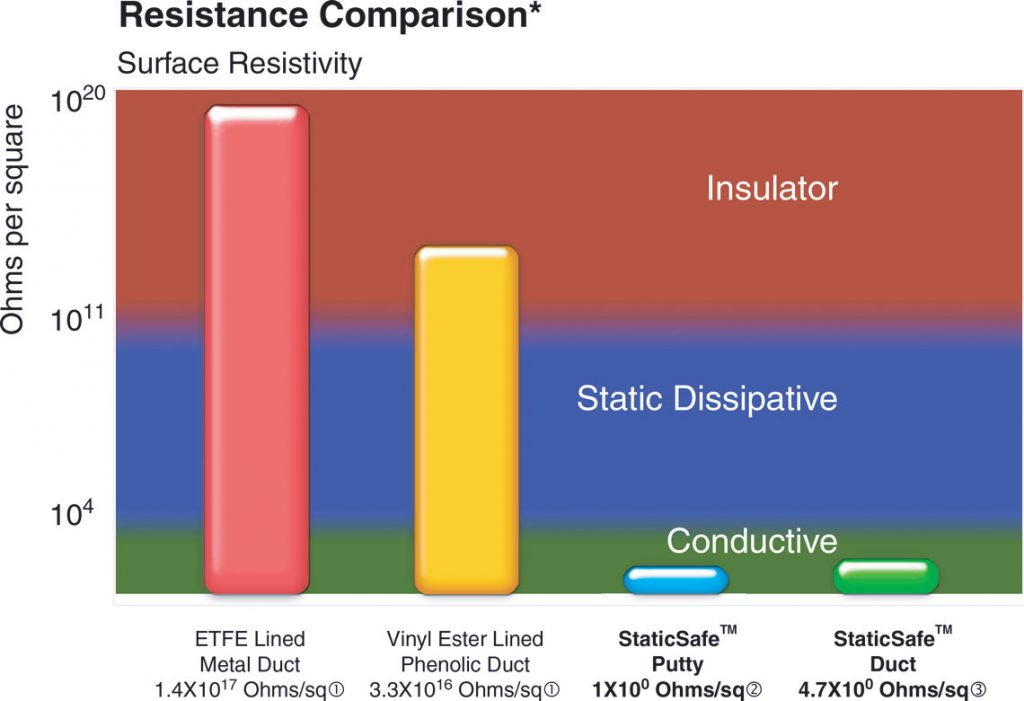

Delsen Test Report – StaticSafe™ has been tested for volume and surface resistivity with a measurement of 0.60 Ohms-cm and 4.7 Ohms per square*, respectively, which exceeds common requirements for conductivity of 1 million Ohms-cm (1×106). Request Delsen test report dated 5/11/01.

1 See Delsen Test Report 05/11/01, pg. 3.

2 See Delsen Test Report 05/11/01, pg. 12. (This uses the following formula: Surface Resistivity= (Width/Potential Electrode Distance) X Resistance (0.33in /0.44in) x 1.21 = .998 Ohms

3 See Delsen Test Report 05/31/00, pg. 3.

Delsen Test Report – ATS StaticSafe™ has been tested for volume and surface resistivity with a measurement of 0.60 Ohms-cm and 4.7 Ohms per square**, respectively, which exceeds common requirements for conductivity of 1 million Ohms-cm (1×106).

* Surface resistivity is expressed in ohms per square, without reference to the size of the square.

The ESD Association Glossary, ESD-ADV 1.0-1994 (1), describes Surface Resistivity in the following way: “For an electric current flowing across a surface, the ratio of DC voltage drop per unit length to the surface current per width. In effect, the surface resistivity is the resistance between two opposite sides of a square and is independent of the size of the square or its dimensional units.

** Resistance (ohms) is the property of a substance to resist the flow of electrical current.