ChemBond

ATS ChemBond™ Putty and Resin

ChemBond™ has been at the heart of ATS modifiable joining systems since 1993. The following condensed literature is available in full size upon request.

- Clean Room Safe

- Low Odor

- No Sanding Required

- Superior Chemical Resistance

- High Structural Strength

- FM Approved as a Joining System

- ChemBond™ offers features important to the cleanroom industry:

- Acceptable Microcontaminant (ng/cm2) Levels

- Extremely low emission of VOCs during installation

- NO SANDING

- High Corrosion Resistance

- High Strength Bonds

- Bonds Multiple Materials

- Ease of Installation

ATS ChemBond™ Resin is a unique product with characteristics that simplify the installation of ATS FXP™ duct. ChemBond™ resin with glass reinforcement can be used to bond two adjoining pieces of ATS FXP™ duct without pre-sanding the duct surface. Because it has minimal odor, requires no sanding, and has no adverse microcontaminant effect on silicon wafers (whether it is a liquid or solid state), it is especially desirable in sensitive cleanroom environments where dust and odors are prohibited and where microcontamination is a concern.

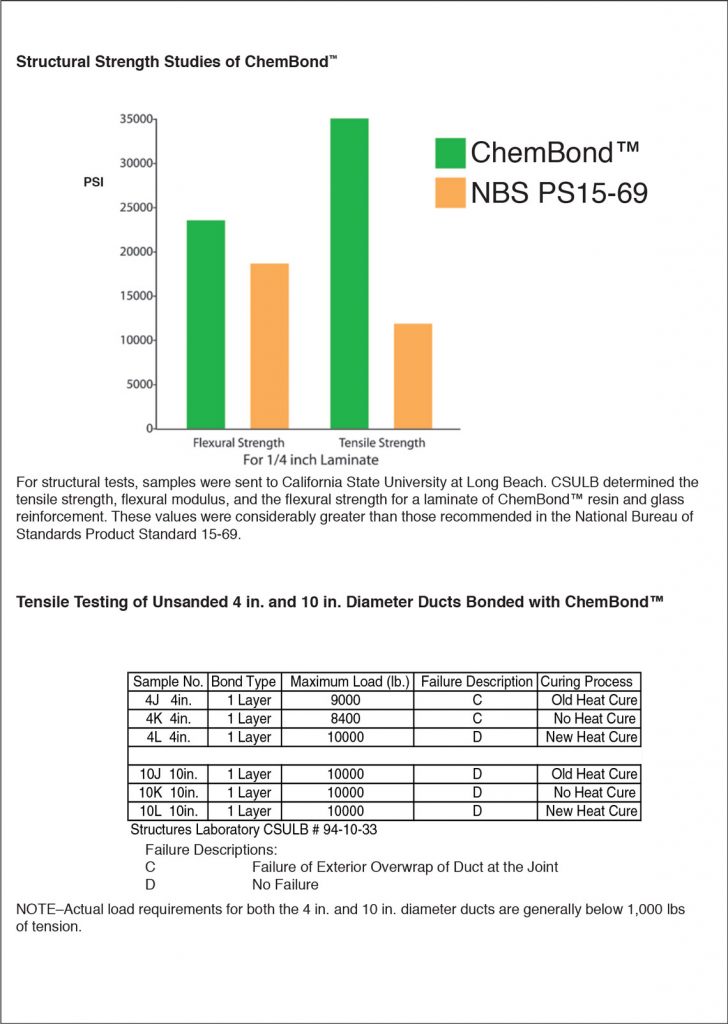

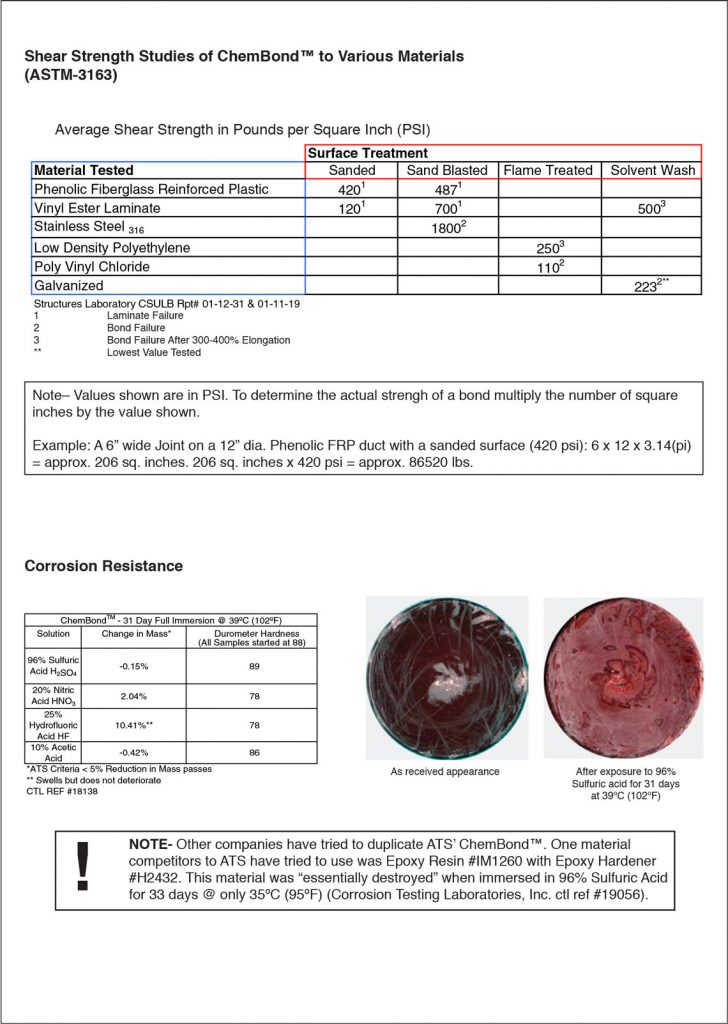

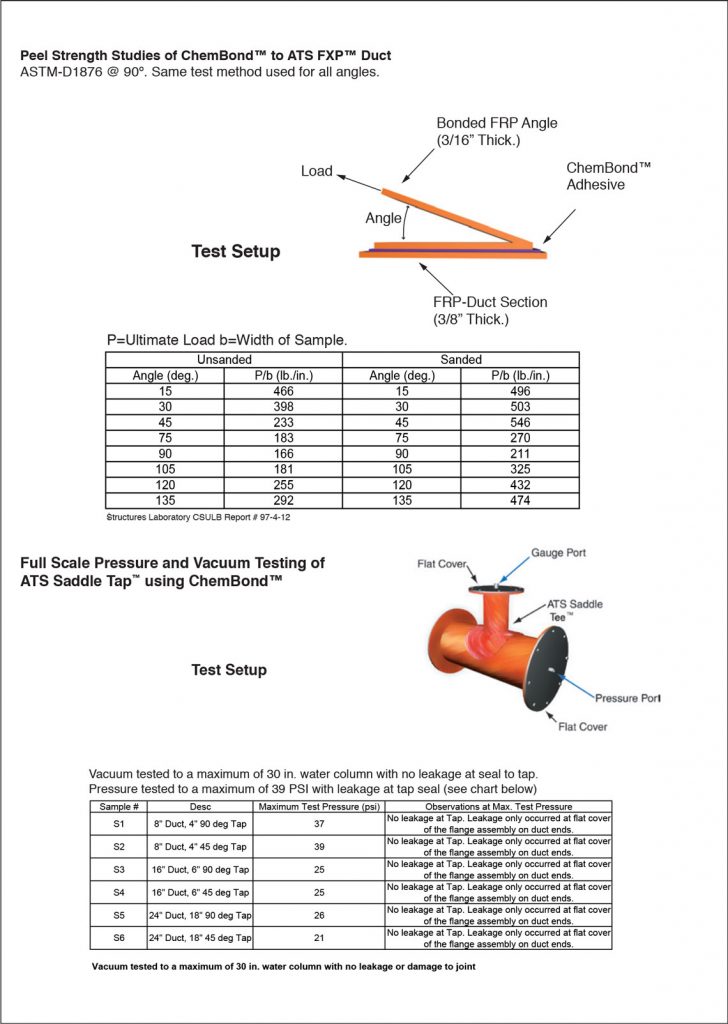

ATS, Inc. has done extensive testing of ChemBond™ to insure it meets the needs and standards of the industry.

- Structural Testing of Joints with ChemBond™

- Peel Strength Studies]

- Full Scale Pressure and Vacuum Testing of Saddle Tap Bonds using ChemBond™

- Corrosion Testing in Full Immersion at Elevated Temperatures

- VOC Offgassing Studies

- Microcontaminant Offgassing Studies (both solid and liquid states)

- FM Approval for use with ATS FXP™ duct Systems